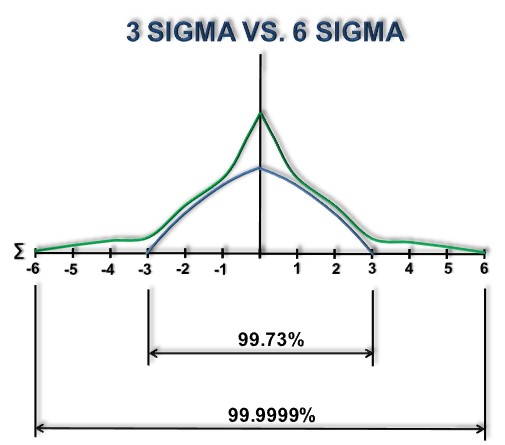

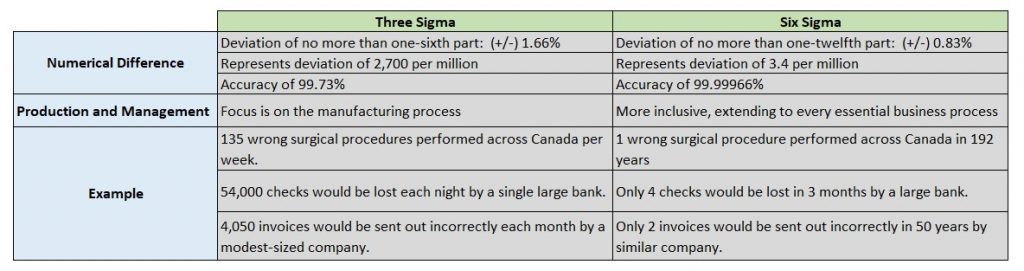

Common probability dictates that 99.73% of all outcomes will fall within 3 standard deviations of the mean (above or below); this is Three Sigma. For most purposes, this is a fine system. There are very few scenarios in daily life or most professions where 99.73% certainty or accuracy is not acceptable. But…manufacturing is one of those exceptions, as are computers.

With modern manufacturing techniques, the massive amount of material output means that even .26% of the whole is a significant number. Particularly in the manufacturing of vehicles, where safety is one of the primary concerns. a .26% defect rate is (quite literally) killer, and results in a functionally massive number of defective parts even though the percentage looks small.

After all, that is still 2600 failures per million parts manufactured…in an industry where parts manufactured are measured in multiple billions.

This is where Six Sigma comes in, ensuring that 99.99966% of the yield works as intended; six standard deviations outward from the mean. This reduces parts per million (PPM) defects to 3.4, a more acceptable number (and one of the best we can hope for).

This issue is exacerbated when you factor in that processes are allowed to deviate by up to 1.5 sigma, making the margin for error even wider.

Worse, this certainty is per process, and the longer a process is the more chances of failure there are, as we learned when we discussed Rolled Throughput Yield (a success rate of 90% does not necessarily translate to 90% of all parts being good, to grossly oversimplify). By Three Sigma levels of quality, 99.73% across a 10 step process is only 97.33% certainty…that’s 26, 700 parts per million in defects at only ten steps out; most modern manufacturing processes can have hundreds, or even thousands of steps. By contrast, Six Sigma standards of quality across the same number is still 99.99966% quality, the differences only becoming apparent as far out as the tenth decimal place; this results in a still acceptable measure of quality loss across hundreds of times exponential loss in quality.

Six Sigma is therefore necessary for modern society to function, as some of our most important achievements and technologies can only function with a minimum of Six Sigma certainty. As a result things like manufacturing, computing, banking, telecommunications, and any sub-industries of those hold themselves to a Six Sigma or higher standard.

Without such standards their industries (and human society as we know it) would be unrecognizably different from what it is today.