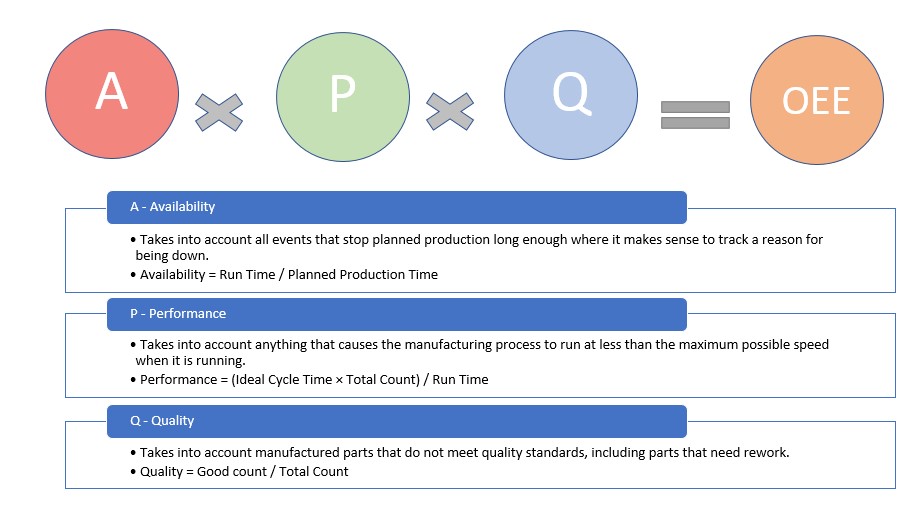

OEE is a simple but effective measure of how much productivity you’re getting out of your manufacturing process. This measure uses three factors: Availability, Performance, and Quality. An OEE score of 100% is essentially perfection (completely on time, no defects, and the process is as fat as possible). Let’ take a deeper look at these three factors:

Availability: This factors in both planned (things like planned maintenance and setup) and unplanned stops in production (this being stuff like unexpected equipment failure). These stops are timed, and compared to the production schedule. The percentage score is assigned for this segment based on how close to this planned time you are. For example, if you estimate it will take 1 hour, and have a planned or unplanned stop of 5 minutes (making you take 65 minutes to complete it) your Availability score will be 92%.

Performance: These take into account slow cycles and small stops. Slow cycles are when things don’t stop, but they do slow down for a period of time for whatever reason. Small stops are very short interruptions in production that don’t quite qualify as planned or unplanned stops. Similar to Availability, these are timed and come out to your Performance score.

Quality: This is the ratio of good parts to defective parts gained at the end of production. This takes into account defective parts that can be fixed, mind you. So if you have 10 total parts, and 8 are good, 1 is reworked, and one is full defective, your Quality score is 80%.

Taking all these factor together gives you your OEE.

So how do you implement this system? Easy. At the start of your project you simply define your parameters, as you should be doing already. You need to know how long each step should take and what your goal is at the end (you’ll always want to try for 100%, even if it’s unrealistic).

Go through an iteration, and capture all the data you need. Every planned and unplanned stop, slow cycle, or small stop and the number of defects and good parts.

Finally, calculate your OEE.

This is one of the best metrics out there for determining how well your business is doing, and I highly urge everyone to start using it, as it’s very simple to implement and tells you almost everything about your end products.