Before officially starting the implementation of an ERP, it is convenient to anticipate some aspects that involve your company and your work team.

Here are some tips that have helped organizations carry out their project successfully:

- Make sure you have the commitment of the management, as it is the central axis of the company and have a global vision, your participation is very valuable and important.

- Implement an integrating leadership, involving all areas and all levels of the organization, in this way you will make them feel owners and part of the project.

- Assign resources to the project (economic, human, infrastructure).

- Clearly and functionally defines the company’s processes.

- Determine objectives and goals to achieve with this project.

- Assign an internal project manager to ensure that the progress and commitments of the project are followed up.

- Become aware of changes in tasks and responsibilities, job profiles and processes which arise from the technological innovation applied in the company.

- Motivate your staff to attend and participate actively in the training sessions.

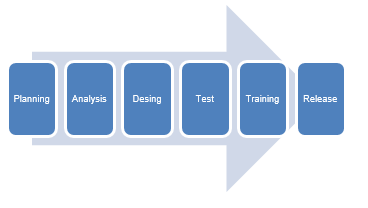

A project to implement an ERP consists of several stages, each with its individual importance, however, in the end a synergy is created between all to achieve the objectives that were set for your company.

1. Planning

The objective of this stage is to put your team in contact with your supplier so that together they define the final and detailed planning of the project, among the activities to be carried out are:

- Present the work team of your company to the consultant who will carry out the implementation.

- Establish a schedule of activities and match the same with the agenda of all involved.

- Create a log of mandatory commitments to start the Project without possible setbacks or surprises.

- Prepare the formats of each of the processes as well as the initial master data that will be entered into the system.

2. Analysis

In this phase, the main thing will be to obtain the list of requirements and agreed functionalities of each of the areas of your company for the implementation and this same list must be validated by each area manager to proceed with the configuration of the solution according to the processes and procedures defined.

During this phase the following tasks are carried out:

- The specific scope of the project is defined.

- Flow diagrams of your processes and procedures are prepared for each operational area.

3. Design

In this stage of the implementation of ERP, the configuration of the solution is made according to the processes, procedures and requirements that were defined in the previous stage.

It is important at this stage that the person in charge of the project on behalf of the company maintain contact with the supplier to validate any doubt that may arise since at this stage the solution is taking shape to be appropriate to the real needs of the business.

4. Test

When this point of the implementation is reached, it is time to validate if what you defined in the analysis and planning is according to the result obtained. This is achieved by performing scenarios of the real operations of the company in situations that recreate the circumstances of day to day.

It is essential that in this phase of the project each one of the persons in charge of the different areas actively participate in the review and validation of each process as well as each tool functionality and the information obtained, to make sure that they are really going to receive that advantage from the system to make their work more efficient. It is very important to confirm that all the processes and key requirements of the day-to-day operation are completely validated and closed at that stage to avoid surprises in the training or project release phase.

5. Training to Use the System

Once the tests and improvements are carried out, all the end users are trained, here the motivation and participation of all those involved is very important since it is when they will have the real experience with the ERP and above all they will be prepared to master the use of the solution.

The total communication with the consultant is very important in this step, all the doubts regarding processes and functions must be expressed, in order to obtain the maximum benefit from the tool.

At the end of the training, the company must ensure that each user is instructed to carry out daily practice operations in the system, as a task, from that day until the release, to reinforce the training received, since otherwise there is a risk that the person loses the knowledge obtained in this stage.

6. Release

We arrive at the end of the implementation process, the release stage, which is the live exit so that the staff can make use of the tool in its entirety with the support of the provider in the initial stage. Once this phase is finished and when the users already manage the solution efficiently according to the assigned tasks, a process of continuous improvement is initiated in order to optimize the work and obtain the expected results in the preparation stage.

The implementation of an ERP represents challenges and changes in the organization, it is a very important project that will demand time, effort and the participation of all the areas that make up the company, however, if there is a mutual commitment on the part of the supplier and of the client throughout the process, the result will be a successful integration of your operations, access to complete information for decision making as well as an accelerated and controlled growth of your company.

Signals that tell you it’s time to change your ERP system

1. Lack of standard features

As time progresses, it is likely that functions that were considered non-essential or a luxury when the system was first implemented, are now a fairly standard practice within your company.

Regardless of whether it is a system function, such as analytics / integrated intelligence or specific functionality for your industry, not being able to use the most efficient technology puts your company at risk of being left behind, especially if competitors have access to this functionality and more.

Ideally, your companies seek to make the most of not only standard features, but also state-of-the-art technology to ensure that you have a competitive advantage.

2. Your system does not offer mobile functionality

In general, businesses are becoming increasingly remote and working on the move, so your ERP system must be able to complement this change in culture by allowing access to certain system functions through the mobile phone, regardless of the Location.

Currently there are ERP systems that offer the same level of information and functionality that are obtained from the desktop on mobile phones, so the work is no longer limited to the four walls of your office. Collaborators can work from home, while on a business trip and even while visiting clients.

3. Bad integration

Ensuring that your business systems work together impeccably is one of the key factors behind how companies can be efficient when it comes to their system processes.

Trusting an ERP system that is not compatible with integration and prevents automatically transferring your company’s data to another system, be it a CRM or another, can cause a significant decrease in efficiency and an increase in manual work.

Modern versions of ERP tend to be more open to integration, which naturally makes it easier for developers to ensure that business systems work collaboratively.

4. The seller does not offer support

An obsolete software is more prone to throw errors and problems in its functionalities and the majority of the vendors offer only a period of time in which they commit themselves to endorse and update an outdated version of the software, with the justification that they are willing to dedicate time to develop and support the most recent version, and in most cases, the previous version.

Most companies that are in a non-compatible and obsolete version of the ERP, begin to feel tempted to stay with the same system until it finally stops working.

While this can save money in the very short term, not updating your ERP system means that you will then have to skip several versions in an update, which will cause the business to have to deal with a much more complex upgrade project. It is also likely that users will face a lot of changes and new features that lead to a much costlier and long transition.

5. The system is not compatible

As we mentioned earlier, as software developers release new updates, they naturally stop actively supporting previous versions, which means that, if a new regulation is introduced, those of previous versions run the risk of not being compatible.

The General Data Protection Regulation (GDPR), designed to strengthen a person’s rights with respect to their personal data, is a key example of how a new regulation may lead to the need to develop a new system ERP

While ERP vendors will develop their software to ensure that their users can comply with the standards, they are likely to only release the patch to recent updates, which makes previous versions unsupported, and they have to spend considerable amounts to make sure they are.

With the cost of default, companies can often spend substantial amounts making sure they meet the requirements, a process that could have been greatly helped if they had kept their ERP system up to date.