The 5S method is something I feel is subconsciously understood by most people. After all, it’s how we clean, it’s how we’ve learned to clean from our parents and what we were constantly pestered through our youth to do. But I also feel like people also subconsciously reject 5S methods, usually out of laziness. Around the house this means not much more than our space feels a little cluttered, but in the workplace, it can cause bigger issues. So today we’ll break down 5S, and why it’s important in a business setting.

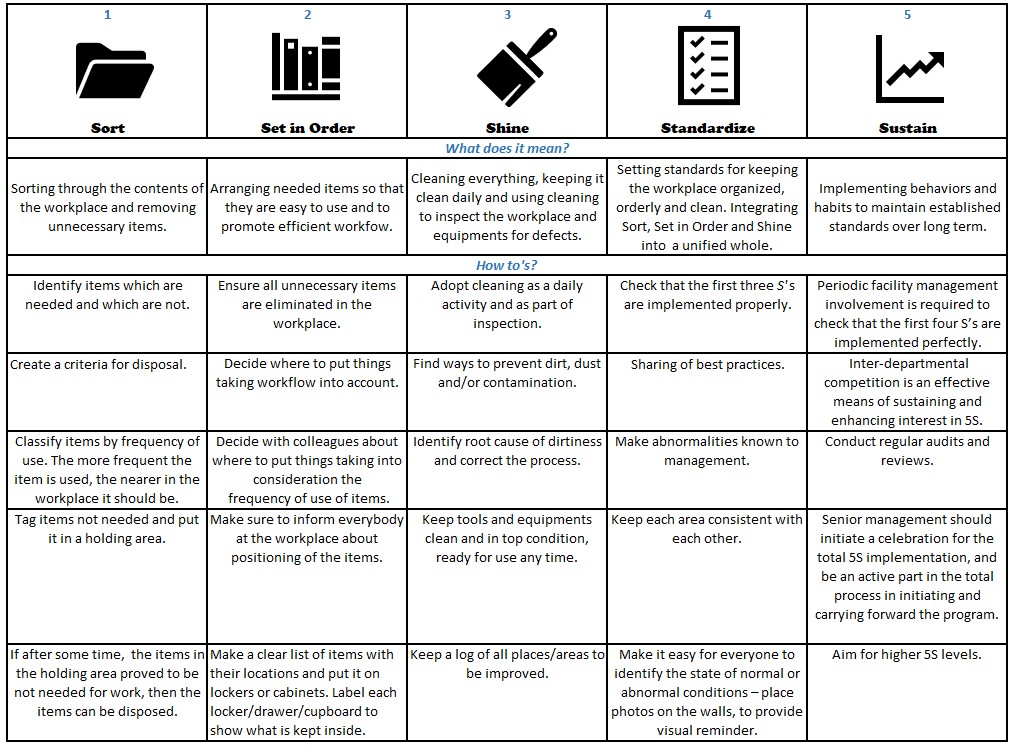

First, what are the 5 S’s? They originally come from 5 Japanese words: Seiri, Seiton, Seiso, Seiketsu, Shitsuke. These conveniently translate to 5 words in English that mean the same thing:

- Sort

- Straighten / Set in Order

- Shine / Sweep

- Standardize

- Sustain

These 5 simple concepts are the core of all corporate cleaning methods, that you’ll find anywhere from the back room of a retail store to (especially) a factory floor (Toyota is notably one of the companies that popularized 5S). Let’s go a little more in-depth on what each S means.

Sort – Remove unnecessary items and get rid of them. By the end of this S you should have:

Sort – Remove unnecessary items and get rid of them. By the end of this S you should have:

- Removed all items not used in the area you’re sorting (note: this does not mean all should be trashed; some may be items from other areas that need to be taken and sorted there). The items to be removed are generally outdated equipment or measurements (or files, if you’re organizing your computer).

- Tagged all items to see how frequently they are used; least frequently used items may need to be removed. Ask your staff to do this, as they generally know better what they do in the day-to-day than you, though get an experienced supervisor to double check. Items to be removed should be marked with a Red Tag.

- Set aside an area for difficult to classify items. Go over this later to finish things up.

| Bad | Good |

Straighten / Set in Order – Organize all the items left after sorting so they can be easily found. Here you want to make sure:

Straighten / Set in Order – Organize all the items left after sorting so they can be easily found. Here you want to make sure:

- Everything has a place near where it will be used.

- It’s compact and stores with a small profile.

- Heavy objects are lower to the ground and easy to reach.

- Everything has a set way of being put away.

| Bad | Good |

Shine – Create a clean workspace, clear of dust, dirt, grime, etc. to make it easier to identify any issues with equipment and reduce maintenance needs. You should:

Shine – Create a clean workspace, clear of dust, dirt, grime, etc. to make it easier to identify any issues with equipment and reduce maintenance needs. You should:

- Improve lighting so it’s easier to see dirt; you can’t clean what you can’t see.

- Keep a chart of whose responsibility it is to clean a piece of equipment that day and have them initial it when they’re done, it shouldn’t take long past the initial cleaning.

- Make sure to not try to have more than one job running at a workspace at a time; that just mucks everything up.

- Clean all equipment that is used, not just the large and obvious pieces. If your wrenches are covered in oil, so will be the table you sit them on; it all matters. This is particularly true if you work in food service.

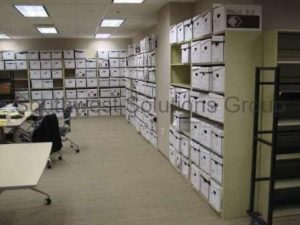

Very, very bad:

Standardize – Exactly what it says on the tin. Create standards for a clean workplace that everyone should follow.

Standardize – Exactly what it says on the tin. Create standards for a clean workplace that everyone should follow.

Some tips:

- Create pictures to show what everything should look like.

- It should always be immediately obvious when something is out of place; that means keeping the standards fairly simple and easy to follow.

- Define specific roles for employees if possible; the more spread out the work is the easier it is to keep to standards. One person may have a hard time keeping everything organized, but a group effort makes this a cinch.

Sustain – Keep everything rolling to the future; your goal is to NEVER have to go through the initial sorting, straightening, shining, and standardizing process again. This is the hardest S, and requires you to make sure:

Sustain – Keep everything rolling to the future; your goal is to NEVER have to go through the initial sorting, straightening, shining, and standardizing process again. This is the hardest S, and requires you to make sure:

- Everybody is committed to following the rules.

- Responsibilities are maintained; it helps if personal responsibility is fostered in employees. Get everyone invested, not just management.

- You audit frequently to prevent backsliding.

- You have solved or are solving the root causes of the issue with organizing. It is hard to shine if the office is often low on cleaning supplies or organize without proper storage space and materials.

Do this and your workplace will be kept clean and shiny, which will foster a more organized and efficient workplace.