A Six Sigma method of eliminating production success reporting bias.

Often, management and financial reporting can contain bias. When a sample of business processes is taken to determine production success, the most-successful part of a sample might be reported to the public and shareholders to paint a picture of success that is greater than reality.

The possibility of biased reporting is especially present in the realm of manufacturing, for example, where businesses must report how many units make it through an assembly line without defect and how many units had to be scrapped and/or reworked.

A part of Six Sigma provides a helpful process to fairly and accurately report production success. This process is called the Rolled Throughput Yield calculation, or RTY. To explain, we will first look at one traditional way that companies might report “success” and then look at how RTY helps reveal the real data.

Our Example Model

Let’s use an example of a manufacturing company that produces motherboards for computers. Each motherboard consists of a board with electrical circuits printed on it and hundreds of tiny components including modules, capacitors, resistors, ribbon wires, and more.

The possibility of multiple boards reaching the end of the line with defects and malfunctioning is very high given the number of parts and the complex processes they must be able to perform. Some units will be scrapped if reworking the defects is not possible or not worth the cost. Others will be reworked.

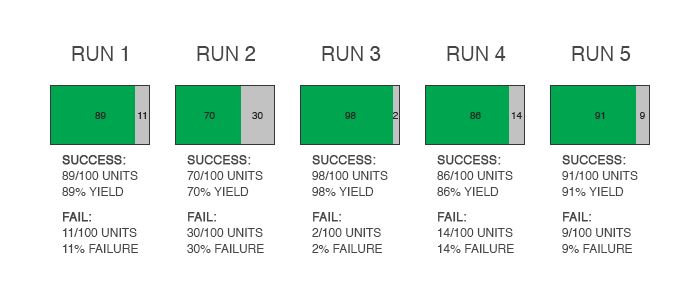

Let’s say that the factory performs five runs each day of 100 motherboards. With each run, only a certain number of boards make it through without defect and are shipped out the door. Here are the results of five runs on a random day:

A Traditional Approach

Without an honest system of reporting, bias could lead management to report on financial reports and to shareholders a number from the above example that skews reality and creates false positivity.

Say that shareholders want to know what the daily number of units shipped and assembly-line success rate are. A traditional approach might lead a manager to pull out their favorite of the above five runs. Favoring Run 3 above, the manager reports to the shareholders that the daily success rate is and whopping 98% with 98 units being shipped per day.

The Rolled Throughput Yield (RTY) Approach

The honest approach would take the less-successful runs into account. The Rolled Throughput Yield (RTY) approach does this. It is a combined approach.

To calculate RTY, simply take the success percentage from all five runs and multiply them:

89% x 70% x 98% x 86% x 91% = 48% Success

As you can see, this is a drastic difference. It is not even half of the 98% that was reported using the traditional approach above.

In Closing

When reporting numbers that impact financial, investment, operational, and other significant business decisions, it is critical to be honest. Reporting a false reality could lead to investors chipping in on bad investments and other problems. Instead report accurately and view the honest, negative reports and critical pieces of information that lead to strategizing how to improve. That is a primary purpose of systems like Six Sigma and RTY.