One of our modern engineering marvels is the Falcon Rocket. While relatively small at almost 65 feet, this partially reusable rocket is the key to our sustainable space flight future. There is always an evolution in any field, and the rocket industry certainly learned its lessons after the era of the Space Shuttle. In a time where every dollar counts, it is important to apply such principles to the aerospace industry, where one vehicle can cost up to $70 million to build. If you can refurbish and reuse a vehicle up to 6 or 7 times, the launch costs of your organization can be reduced. Customers are drawn to the most affordable and efficient supplier, and SpaceX has managed to accomplish this mission in a very eloquent way.

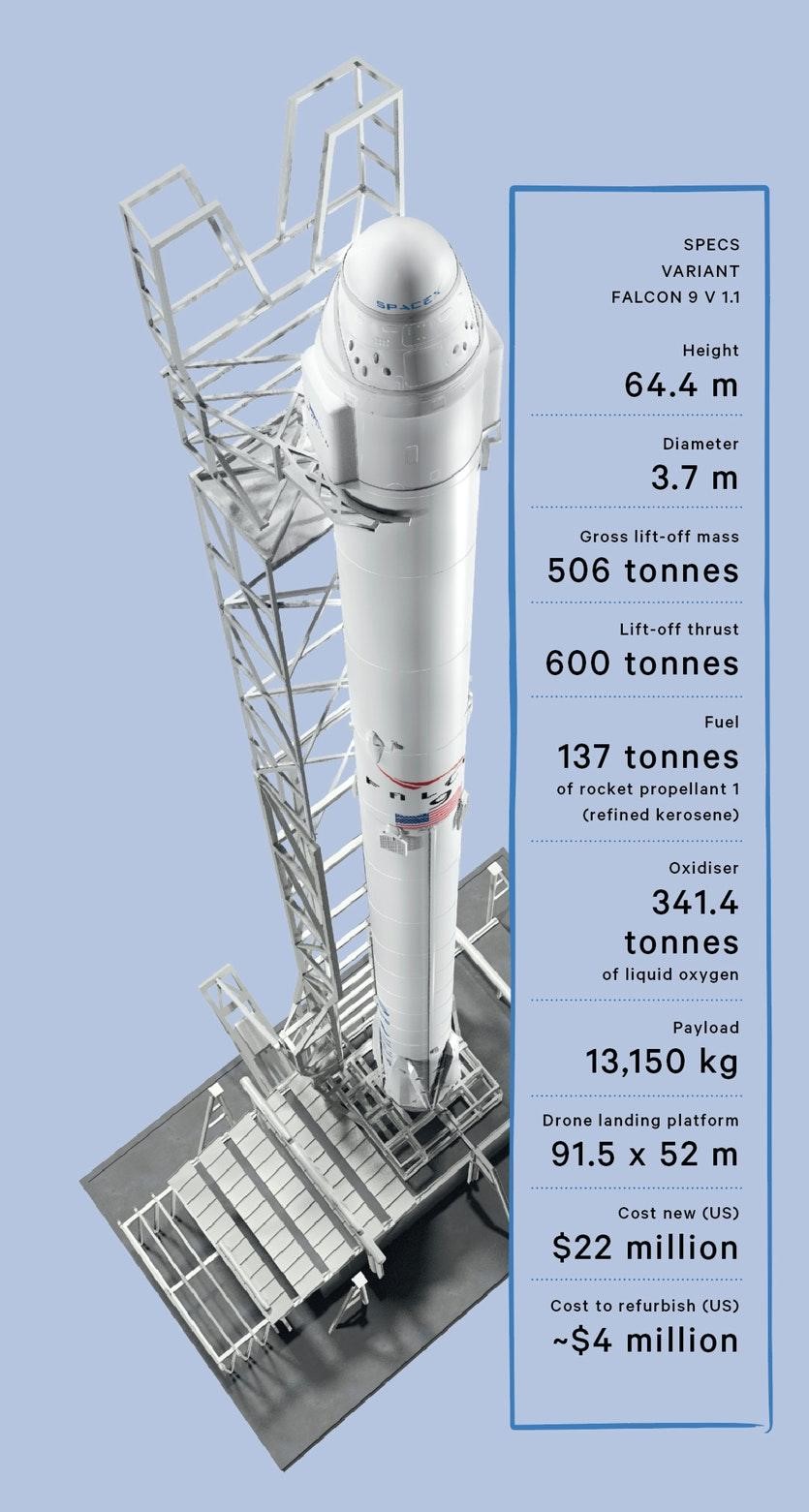

Falcon 9 Design

The Falcon 9 is a partially reusable two stage rocket. The rocket’s boosters, the primary part of the core of the vehicle, are able to carry the unit to lower Earth orbit, and then gracefully return themselves back to the planet, and either land at Cape Canaveral or on a drone ship at sea. The Falcon is designed with 9 very powerful Merlin engines that enable the vehicle to throttle through various stages of power as it navigates through space and the Earth’s atmosphere on ascent and descent. With time and system evolution, the current Falcons always land and always return to Earth safely. As an innovative organization, Spacex has found ways to keep its unit as sustainable as possible. Below are a few ways that they were able to optimize the boosters to enable a return to Earth in a safe manner.

Thrust Vector Control

The Falcon 9 boosters have built in thrust vector control that enable the unit to actually return to Earth and land vertically on its target location. Utilizing various technologies inclusive of nitrogen thrusters, the Falcon 9 integrates these thrusters with a grid fin system that keeps the system ready for a proper landing.

Engines As Brakes:

The Falcon 9 Rocket first stages utilize their engines as their brakes. When the rocket leaves the Earth, it initially is jettisoned from the second stage and the payload or Dragon Capsule. Upon landing, the Earth’s gravitational forces do accelerate the unit, and as a result the system designers have utilized some of the engines as brakes for the Falcon as it lands. Usually up to three of the engines are utilized in the process of braking the Falcon as it lands, and allow the unit to balance itself as it returns to its landing position.

The tweaks to the Falcon 9 integrated over the past two decades of its existence are by no means exhaustive. Changes are always being made to the unit, as the most important mission is the one that the company is going to fly next. Via the collection of process data, the team is able to identify how best to improve their launch and recovery process and apply that to future missions. When it comes to recovery, the organization is expanding its ability to collect payload fairings as they return to earth. The fairings do cost a few million dollars to build, so the ability to recapture them in the organization’s recovery ships are always process optimizations that they welcome.

SpaceX also recovers and refurbishes its Dragon Capsules, as a means to save on process costs as well. With missions to the International Space Station lasting up to six months at a time, once a capsule returns to Earth, the team will thoroughly inspect it, and ensure that the relevant sections such as the Heat Shield, and functional systems are fully operational before cleaning it up and returning it for use on another mission.

SpaceX as an organization has revolutionized the way that Space is viewed. Via its baseline business operations to carry payloads to the Space, and now its commercial crew program, it has definitely taken the time to ensure that it is doing so in a sustainable manner. With this mindset, they aim to translate their sustainability mandate to larger missions like the Moon, Mars and beyond. As they take the efforts to become more sustainable, they are setting the example for other organizations in the aerospace realm to actually be able to operate in a more sustainable fashion, as they too embark on a journey to explore the solar system. It takes a lot of vision to be an innovator. It takes even more vision to remain at the top of your game.