“Man is to technology what the bee is to the flower. It’s man’s intervention that allows technology to expand and evolve itself and in return, technology offers man convenience, wealth and the lessening burden of physical labor via its automated systems.” ― James Scott, Co-Founder, Institute for Critical Infrastructure Technology

Industry 4.0 is emerging as part of the next generation of plant management and control. With the advent of advanced robotic systems, industrial process operations are bound to change. Many processes, such as car manufacturing, drink bottling, drink labelling and even pharmaceutical manufacture utilize robots in their production processes, in order to ensure that the appropriate quality control is maintained. In the surgical realm, there are robots that do exist to assist with the surgical process and provide procedures with the appropriate accuracy needed during minimally invasive surgeries.

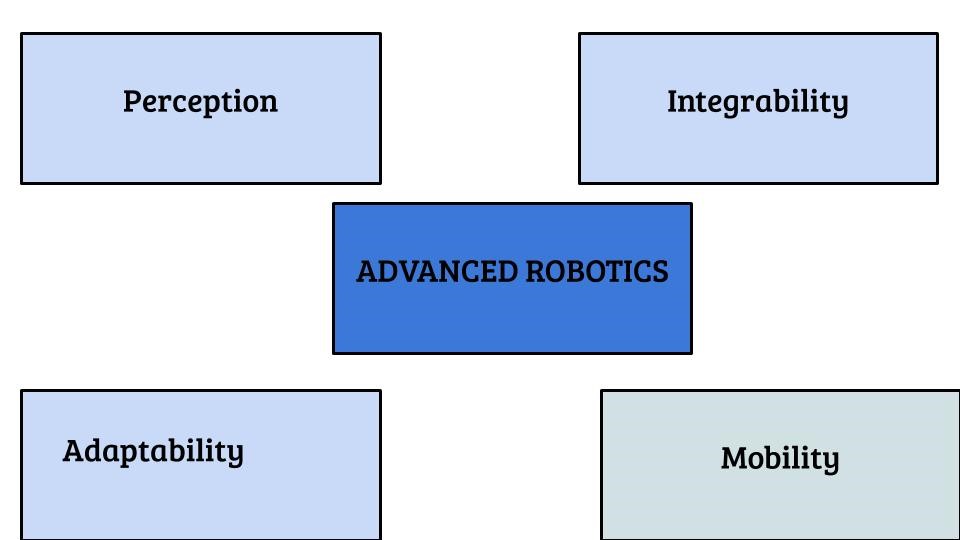

Robots have existed for a few decades, and have been evolving with the advances in technology from a hardware and software standpoint. The evolution of these surgical robots has produced robots that are superior to preceding generations due to their traits of improved perception, adaptability, mobility, and systems integration.

New robots are much easier to configure than preceding generations, and with their robustness, there are the means to ensure that operating systems have stable and efficient operations. As with all new technologies, a key limiting factor, or barrier to entry is often the associated costs. New technologies tend to be more expensive than technologies that are mature and have had a chance to adapt to customer needs over time. Advanced robotics in the manufacturing industry is destined to decline as industrial advances in reduction of processing costs of components such as sensors, software, and computer hardware decrease with time.

In industry and business, the key to any process is always ensuring that the economics of a process are well factored in. If more companies are able to afford the price point of critical industrial robots, then they will be able to utilize them in their operations. How then, do organizations ensure that they are in a position to adapt such technologies, and how do suppliers help them achieve their objectives.

In the initial stages, suppliers can ensure that they are able to discuss the appropriate financial details with their potential customers and even create a bridge between the customer and an appropriate agent that will enable the transaction to be made. As long as the critical parameters of performance and gains exceeding the costs of the robots is proven, there will always be a demand for the industrial robot.

In a world where human error can cost millions in insurance costs, utilization of advanced robots to perform tasks that may seem mundane, in a very economical and repetitive way without tiring, will be the key to organizational success.

Factory of the Future

Advanced robotics is an essential tool in the management of the factory of the future. Via improving critical operating parameters such as production output and even facilitating just in time operational strategies, manufacturers will be able to customize their processes as necessary.

Operations Managers can expect to see improvements in their:

- Output: Maximizing and exceeding production levels is what keeps every production manager’s heart beating. The more output you can make on less resources and costs, the better the final price point for a manufactured product will be. Assembly line management is one aspect of operations that will have to be optimized to match a seamless continuous operational flow. Advanced robotics excels in this area, because it irons out the microstops that are associated with traditional robots. Without microstops, more production can be maximized in between service times.

- Quality: Quality is king in all aspects of industrial output. Customers want products that will suit their needs, at a price that they can afford. From a human perspective, with time, there will be a point where production quality output will wane with time. With advanced robotics that can outperform humans, some tasks will be more reliably delivered at a required standard quality.

- Safety: When it comes to some industrial processes, there may be certain operational conditions that are deemed unsafe to humans. These include zones of high altitude, high temperature or enclosed spaces. Robots are able to navigate such planes with minimal exposure to damage.

Keys to Success

As with any new technology, advanced robotics on its own will not yield great results. Advanced robotics integrated into process systems, and utilized to make appropriate decision making choices, can yield savings of up to 40%, compared to previous operating costs.

Reference Article:

https://www.bcg.com/publications/2019/advanced-robotics-factory-future.aspx