SIPOC is a high level management tool that simplifies the variables of any given process into five segments. SIPOC is the acronym of these five segments:

- S for suppliers,

- I for inputs,

- P for process,

- O for output and

- C for customers;

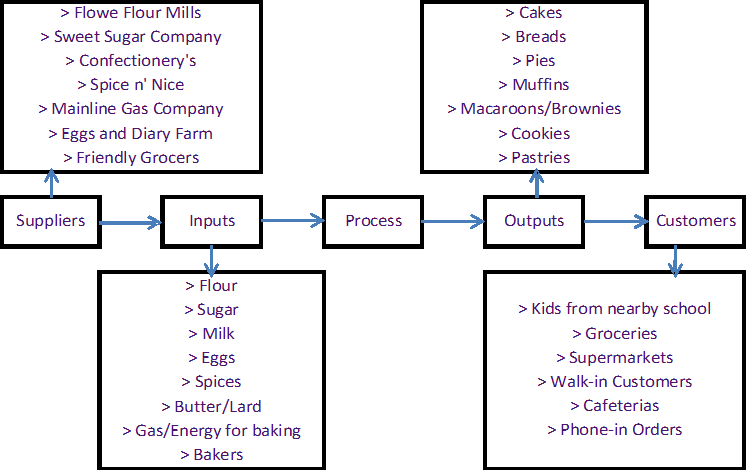

A basic SIPOC diagram would look like this:

Basic SIPOC Diagram

Aside from managers, process improvement and audit teams also rely on SIPOC for a quick summary of a process. Each phase of the process is clearly defined. It shows the vital relationship of one phase to another and how they affect each other’s performance. The diagram also shows the flow of the process, making the determination of a failure easier to pinpoint.

SIPOC is best accomplished in team work and brainstorming sessions. During sessions, team members will determine all the variables that are relevant to a given process. Let’s use the baking process as an example for this discussion.

The first step of the process is to determine and list down the its variables. In our example, we can list the following as our suppliers, inputs, outputs and customers. This is just a short list intended to demonstrate the method. When working in a real setting, you have to list everything that is relevant:

SIPOC Diagram Variables

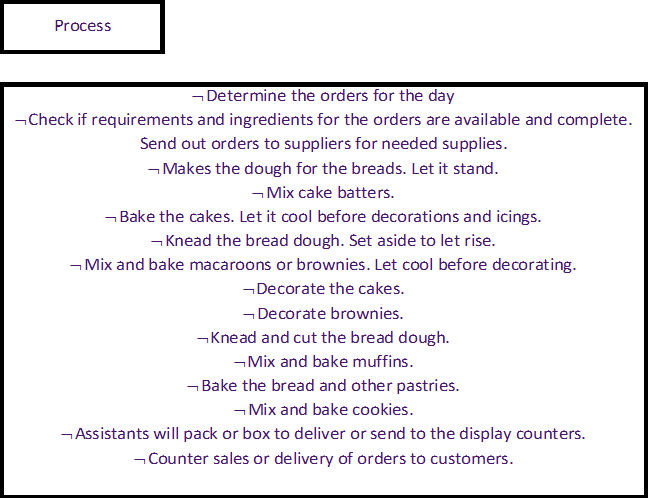

Next we establish the steps within the process. For this example, the process map will look like this:

SIPOC Process Map

Analyzing the SIPOC Diagram

Before you can analyze your SIPOC Diagram, you first have to establish the requirements for the inputs and outputs.

Inputs – Inputs are the raw materials used in the process and the main components of your output. Below is the list of input requirements for the baking process:

- Raw materials should be fresh.

- Should be reasonably priced.

- Available when needed.

Outputs – Outputs are the end product of the process. These are also the products that you will pass on to your customers. Your output should always mirror the company’s goal and positioning in the market. Below are some possible output requirement of our sample process:

- Freshly baked.

- Delicious and well presented.

- Affordable.

- Easily accessible.

Now we can analyze if the suppliers are addressing the input requirements and compare if the customer’s needs are aligned with the products that we are offering.

Suppliers – Your suppliers should be able to address the needs or specifications of your inputs. Some of the guiding questions to help you determine if you are working with the right suppliers are:

- Can the supplier provide adequate supply when needed?

- Does the quality of supplies meet the input requirement?

- Are the prices feasible?

- Does the company have a backup supplier in case of default?

- Is it financially and reputation-wise advantageous to be connected with the supplier’s company?

Customers – Customers or the end users of our products are the people or entities that are willing and able to pay for what we are offering. In this case, we listed walk-in customers as well as retailers. Using VOC (Voice of the Customer) we use the guide questions to determine our customers’ needs and wants:

- What is the most important bread quality that you require?

- How much are you willing to spend for a loaf of bread? For a medium sized birthday cake?

- Where do you buy your bread supply? How do you buy specialty cakes?

- How often do you buy pastries?

Your customers’ feedback or your projected customers’ needs should be addressed by your output. In case of misalignment, go back to your process. You might need to modify the process.

It is not unusual to employ SIPOC on established processes if there’s a low turnout on sales or output or if the expense ration against income is high. SIPOC will help process auditors to determine if the process is still working for the business. From the analysis, managers will have a clearer idea of whether to streamline on expenses or infuse more resources to improve the efficiency of the process.

COPIS

When creating a new process, planners usually follow the COPIS (reversed SIPOC) model. This is common when putting up a new business or creating a new line of business within an established one.

You will start from the “customers” by getting the VOC (voice of the customer) through surveys and interviews or by simply projecting needs through feasibility studies. Upon reaching a clear idea of the target customers’ needs, you derive a product to address the needs.

When you already have a product in mind, the next step is to create a process that will generate that product. Bear in mind the requirements of the output should be a major consideration when designing the process. After establishing the process, the next things to think about are the inputs, or the things that you will need for the process to be executed.

Lastly, determine the suppliers that can provide you the necessary inputs. Again, input requirements must be followed. For the whole process to work and bring favorable business, all elements in SIPOC should be aligned and supports the ultimate goal of the business.