Worldwide, all organizations are concentrating on LEAN manufacturing and LEAN processes. The famous ‘Toyota Production System’, which is being followed in various organizations today also, insists on reducing waste and optimizing their processes. Toyota Production system insists on reducing the three inefficiencies to attain a LEAN process. They are:

While ‘Muri’ and ‘Mura’ are taken care by the normal continuous improvement initiatives, Muda takes extra initiative to identify and eliminate or reduce.

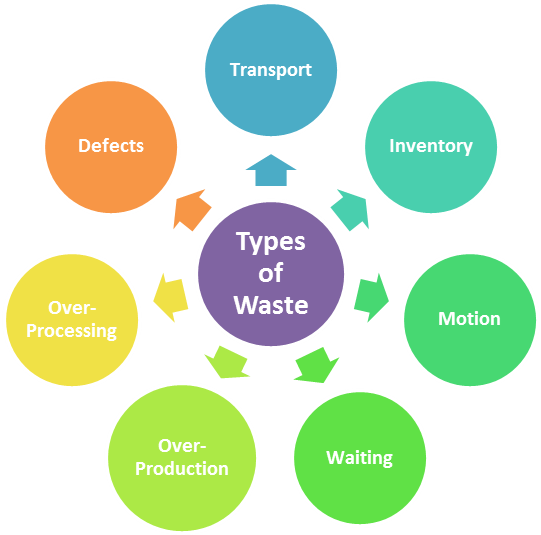

Muda or Waste is anything that does not add value in the eyes of a customer or anything that customer is not ready to pay for. In short waste is a non-value adding step or task that exists in a process. Therefore it becomes necessary for a Quality Professional to understand the types of waste that exist in a process. Experts have identified and classified the wastes into seven categories. They are:

Transport: Any unnecessary movement of Work in Progress or raw materials is a form of waste. This may cause damages to materials, and may also increase the cycle time of production and thus is a waste.

Inventory: Purchasing and storing raw materials, and stocking Work in progress to wait for future processes is a waste.

Motion: Unnecessary movement of machineries and movements of operators can cause wear and tear, fatigue respectively.

Waiting: In a series of steps for processing a material if one of the steps is slow, then it accumulates Work in Progress which is a waste.

Overproduction: Producing items that are in excess of customer demand.

Over-Processing: Providing features that are not demanded by customers, and fine tuning to levels more than that are prescribed by customers, adds to cost of manufacturing which is a waste.

Defects: Finally, the most important and prevalent type is defects. Defects are not acceptable by customers. To avoid this, a Quality check process, rework process should be established, which adds to cost. Therefore defects are a major form of waste.

Irrespective of the nature of process whether it is a manufacturing process or service process in an office environment, these wastes are prevalent and increase the Non-value adding cost. Thus these seen types of waste can be helpful to identify and eliminate these wastes.