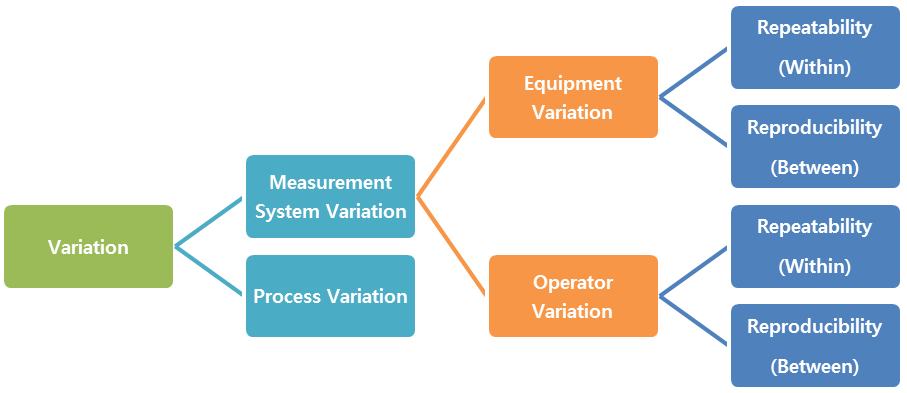

In any process, Variation is the reason for most of the problems like customer complaints, defects, inefficiency and many other problems. The variation might arise in different ways: one from the process, and also from the measurement system used for measuring process performance.

While we would want to concentrate on reducing the process variation, if the measurement system is prone to variation, whatever steps taken to reduce process variation might go as a waste or not produce desired effects. Therefore, the correct approach would be to fix the variation in measurement system and then proceed to Process Variation reduction.

Measurement System Analysis is an approach used to evaluate the performance of a Measurement System to produce measurements that are accurate and not prone to variation. Measurement system is a combination of Measuring Equipments and operators (Humans who measure the readings in equipment).

Gage R & R is a tool, to measure the different types of variations existing in a Measurement system.

There are three types of metrics available in Gage R & R:

- Repeatability: To assess the variation of individual operators or equipment when measuring a same item repeatedly. This helps to check if the operator is consistent in measuring.

- Reproducibility: This is used to check if different operators or/and Equipments produce same readings/measurements when measuring a same item.

- Bias: There are chances that some particular operator may tend to produce a different measurement for one particular equipment alone. This interaction between operator and equipment should also be identified and removed.

Thus Gage R & R stands for Gage (Equipment) Repeatability and Reproducibility.

How to perform and interpret a Gage R & R?

The below is a very broad level overview of how to perform a Gage R&R study:

- Identify the Equipment and Operators who are involved in the process and are part of the Measurement System

- Select the items to be measured.

- Design the number of experiments and trials;

- Perform the first trial for all operators with respective tools

- Make note of all the readings.

- Perform the second trial, at the prescribed interval.

- Similarly perform the trials for all items.

- Calculate the Mean and Standard Deviation for all trials of Appraisers, All tools and overall.

- Calculate the Precision-Tolerance Ratio for:

- If Precision-Tolerance Ratio:

- P/T Ratio < 0.1 , then the Measurement system variation is negligible; The system is good enough to proceed

- P/T Ratio >0.1 & <0.3 , then the Measurement system variation is acceptable; The system is good enough to proceed

- P/T Ratio >0.3, then the Measurement system variation is unacceptable; the system is needs to be modified to reduce variation.

Thus a Gage R&R can be performed and used for understanding and analyzing variation. Gage R&R can be used for both continuous and attribute data. Therefore it is used in both manufacturing industries and in back office processes.