Product development inspired by customer desires.

House of Quality refers to a well-known process for product development that is inspired by customer desires for product or process development and anchored by the capabilities and resources of the organization seeking to meet those desires. It is a process of listening to customers, translating their desires into a written plan, prioritizing steps of execution based on what is most important to the customer, and putting a realistic plan on paper.

What is QFD?

House of Quality is a part of a larger process called QFD, which stands for Quality, Function, Deployment. This represents quality-monitoring, a focus on the function of execution of a quality plan, and the application of resources for deployment of that plan. While the name, QFD, does not encapsulate all that QFD covers, it is a name that has been around for quite some time. It is familiar, so organizations continue to use it. The House of Quality name comes from the very useful diagram used to make this plan that resembles a house, which we will dig into shortly.

Primary Purposes of QFD & House of Quality

We’ll now cover some primary purposes of QFD / House of Quality:

-

Understand Customer Desires

Many times, customers need outside perspective to discover what they really need to build their product or process. The goal is to understand customers perhaps even better that they understand themselves so as to open their eyes to ideal solutions. -

Understand Customer Priorities

During the interview stage, get to know customer needs, but then break those needs down into prioritized parts. For example, if a customer is building drones for media production, how important is battery life compared to camera quality? How important is aesthetic compared to quality of the drone body? Weights are assigned to each quality based on what is most important to the customer. How well each need is met is ultimately how the customer will judge your solution’s value. -

Departmental Buy-In

Often, disagreement or misunderstanding between departments of a customer’s organization can occur in relation to what is actually needed. Marketing may think that a drone with trending features is top priority, but engineering may think that overhaul of a problematic part is top priority. The process helps create a plan that addresses all true priorities and to which all departments can agree. -

Translate Customer Desires Into Goals & Technicalities

This is the heart of the QFD process where the recorded desires of the customer are ranked by priority and specific process and resource planning takes place. They are laid out onto a useful diagram labeled the House of Quality. -

Specify Traceable Requirements

Specific requirements for the execution of the customer’s product or process should be laid out. The how and why questions should be answered in the plan–how are we meeting the client’s requirements and why are we doing it this way? The written requirements and should be specific enough that their completion and success are traceable. One should be able to work forward and backward in the plan and determine easily whether or not the overall plan is being executed successfully. For example, if there is a question on why something is done a certain way, one should be able to trace back to the beginning of the process to the initial requirement that determined the process needed to meet that requirement. -

Provide Structure

It is easy for customers to jump all over the place stating what they desire and tossing out ideas. But, at the end of the day, your role is to hone in on what they want and provide a logical, executable, traceable structure to organize their ideas. -

Allocate Resources

Whether developing a physical product or creating a process for a customer, resources are needed to do so. Humans, machines, computers, construction materials, disposable materials and more must be accounted for. What do we have available to us and what do the available resources allow us to do? Answering these questions is a critical part of execution.

House of Quality Diagram

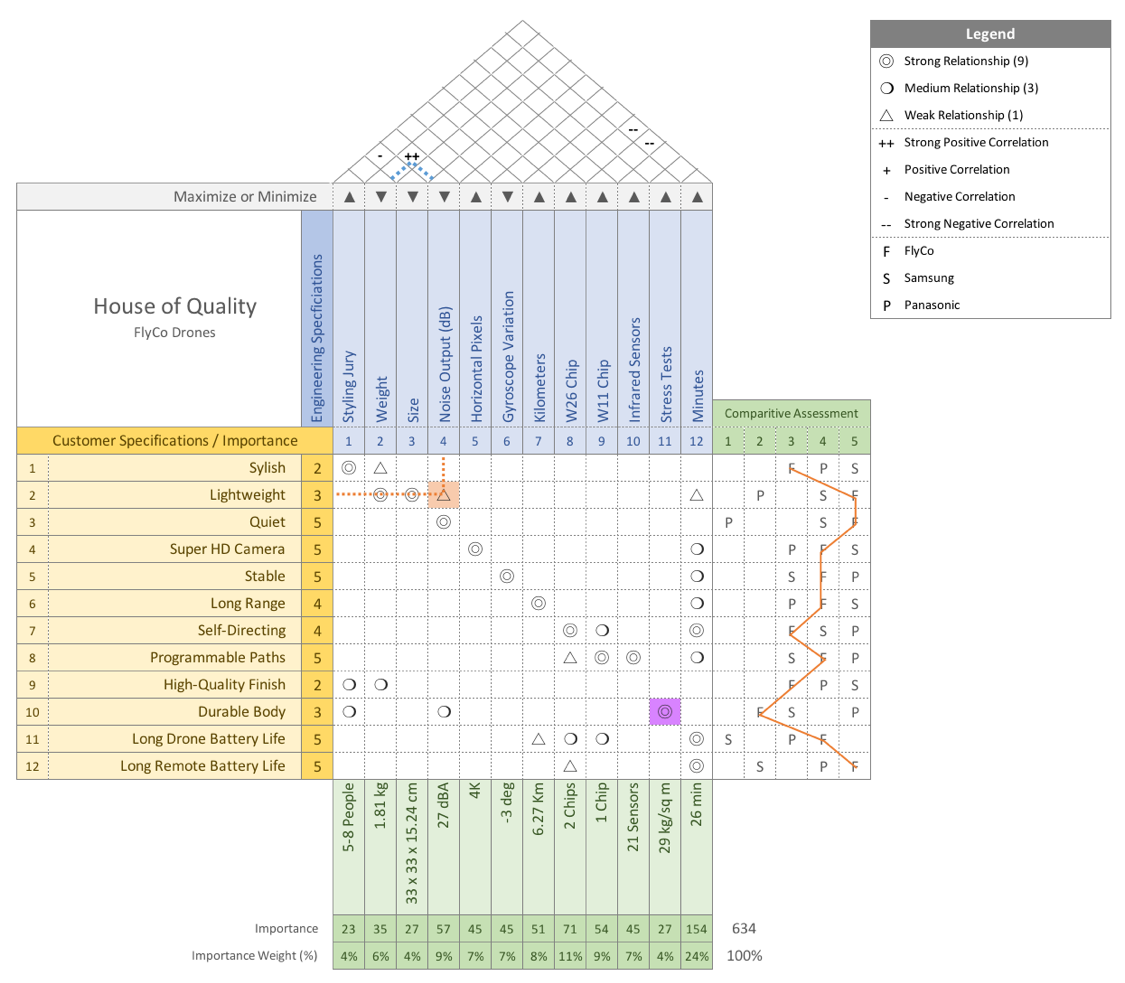

Below is an example of a House of Quality Diagram. We will now walk through a summary overview of its various parts. We continue our example of a media-production drone manufacturer.

The Customer Specifications section to the left lays out the specific priority features on which the customer has set focus. The numbers just to the right represent their importance to the customer on a scale of one to five. The Engineering Specifications section displays engineering methods needed to measure and execute production. At the base, the engineering specifications are detailed in specific measurements.

The center grid containing symbols displays how strong a relationship each customer specification has to each

engineering piece. Referring to the Legend, a ◎ indicates a strong relationship with a weight of 9, a ❍ is a medium relationship with a weight of 3, and a △ is a weak relationship with a weight of only 1. For example, if you cross-reference the Lightweight specification with the Noise Output (dB) engineering specification (refer to the orange dotted line, you will find a △, indicating a medium relationship between how heavy the drone is and how much noise it puts out. A cross-reference of Durable Body and Stress Tests shows a ◎, indicating a strong relationship between how durability is judged and in-house stress tests.

The top portion, the “roof” of the house, displays potential conflicts between engineering specifications. Referring to the blue dotted line, you see that there is a strong positive correlation between the unit’s weight and the noise output. When the weight goes up, the propellers must work harder to keep the drone suspended, so the noise level also goes up. Just below the roof, the up and down arrows indicate which direction the customer would like each engineering specification to go. For example, they want style up, noise level down, and battery run time up.

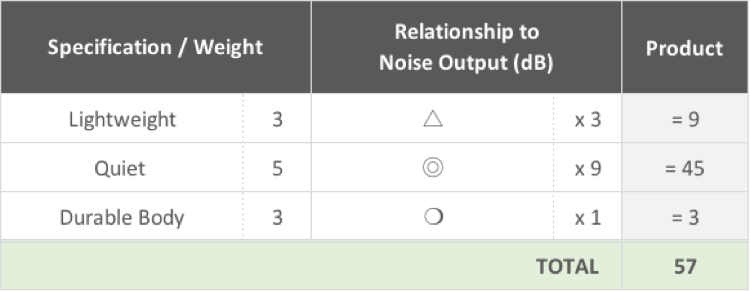

The Importance numbers and Importance Weights at the bottom are the overall importance after evaluating customer importance and engineering relationships. To obtain these numbers, calculate the product of each customer importance weight and the value of the relationship symbol for each specification and engineering specification. For example, the overall importance of minimal noise output is obtained as follows:

The total of all importance weights (634) is shown to the right. Per the above calculation, minimal noise holds an importance in the group of engineering specifications of 57. This number (57) divided into the total weight of 634 gives minimal noise output a percentage importance weight of 9%, shown below the weight numbers.

Referring to the weight numbers and percentages at the base shows that runtime Minutes is the most-important specification to focus on at 154 or 24%. Style, Size, and Stress Tests are the least important area of focus at 23, 27, and 27, which all round to 4%.

Lastly, the Comparative Assessment section to the right displays a trending line indicating where your model stands in the market compared to other brand models of similar specifications. Three brands are represented with F representing FlyCo (your brand), S for Samsung, and P for Panasonic drones. Each brand’s effectiveness in executing each specification is rated on a scale of 1 (poor) to 5 (excellent). For example, refer to the Stable specification. Going to the right under Comparative Assessment, you will see that Samsung (S) drone stability is mediocre, FlyCo (F) is good, and Panasonic (P) is at the top with an excellent rating of 5. For Drone Battery Life, Samsung rates poor, Panasonic is in the middle, and FlyCo (you) are rated good with a rating of 4.

In Closing

There are various levels of detail into which one can go using the House of Quality diagram. Some might include ratings for each engineering specification that indicate technical difficulty of execution, and so forth. But the example above is widely applicable and fairly detailed.